Regulatory and Industrial Standards for the Qualification of Premises and Air Handling Technology

Excerpt from the GMP Compliance Adviser, Chapter 3.J.1

9 min. reading time | by Harald Flechl

Published in LOGFILE 14/2023

In the pharmaceutical industry, qualification and validation are the prerequisites for GMP compliant production of medicinal products. Qualification relates to the equipment (rooms and premises, plants and equipment and IT systems), while validation relates to the processes (production and packaging, cleaning, IT processes). Qualification and validation verify the suitability of the equipment and processes for the intended purpose

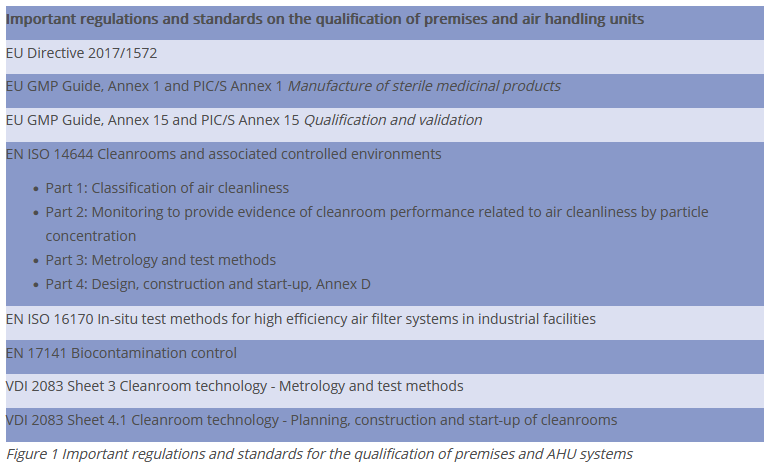

The legal basis for this is provided by EU regulations, in particular Commission Directive (EU) 2017/1572 which was transposed into national law together with other European directives. For Germany, this is the Ordinance on the Manufacture of Medicinal Products and Active Ingredients,for Austria the Pharmaceutical Works Ordinance.

For premises and equipment, it is defined in Article 8 of the EU Directive as follows (shortened excerpt):

(1) ...the premises must be suitable for the intended operations...

(2) ...any adverse effect on the quality of the product is to be minimised...

(3) ... they are to be subjected to appropriate qualification and validation.

Paragraph 3 guides us to prove the suitability of the rooms and air handling units (AHUs), that is their qualification. A documented proof of suitability is therefore mandatory under the GMP regulations.

Annex 15 to the EU GMP Guide and the identical Annex 15 to the PIC/S Guide to Good Manufacturing Practice of Medicinal Products provides assistance or guidance on how this proof of suitability for the qualification of premises and AHUs in the pharmaceuticals industry can be carried out. EU Annex 1 applies specifically to the manufacture of sterile medicinal products, which, however, again refers to Annex 15 for equipment qualification.

For details of the implementation of the air purity classification, reference is made in Annex 1 to EN ISO 14644-1. For other metrological requirements of rooms classified as cleanrooms, EN ISO 14644-3 is particularly suitable. Among other things, it contains detailed instructions for the acquisition of further physical measured quantities, which must be specified in the user requirements specification (URS) with regard to the process/product requirements prior to qualification. In addition, it specifies minimum requirements to be met by the measuring instruments. Alternatively, the guideline VDI 2083 Sheet 3 Cleanroom technology Metrology can be used. However, it is not yet harmonised with EN ISO 14644-3.

The EN ISO 16170 procedure In situ test methods for high efficiency filter systems in industrial facilities is also frequently used for filter tests in exhaust systems. Here, procedures are described for testing filters that are not accessible from the room as so-called "terminal" filters but are integrated into air ducts as exhaust or supply air filters. It applies where these filter units are installed in facilities that process or handle toxic/radioactive/biological material. They are used to largely clean the air leaving the room from airborne particles before releasing it to the environment. This international standard excludes those applications already covered by EN ISO 14644-3, but can be applied mutatis mutandis to high performance filters in pharmaceutical exhaust air systems.

For microbiological assessments, EN 17141 Biocontamination control is often used as the basis (the previously applicable EN ISO 14698 was withdrawn in 2021). This sets out the requirements, recommendations and methodologies for microbiological contamination control in areas controlled for cleanliness. However, this document is limited to viable microbiological contamination and excludes all considerations of endotoxin, proteinaceous-infectious and viral contamination.

Additional important guidance regarding Planning, initial commissioning and technical approval can be found in the informative Annex D to ISO 14644-4. Documents from the initial commissioning can partly also be used for the qualification.

The most important regulations and standards are summarised in Figure 1.

Do you have any questions or suggestions? Please contact us at: redaktion@gmp-verlag.de