Risk Analysis in the Equipment Life Cycle

The text is a translated excerpt of the German GMP knowledge portal GMP:KnowHow Anlagenqualifizierung (equipment qualification).

5 min. reading time

Published in LOGFILE 15/2022

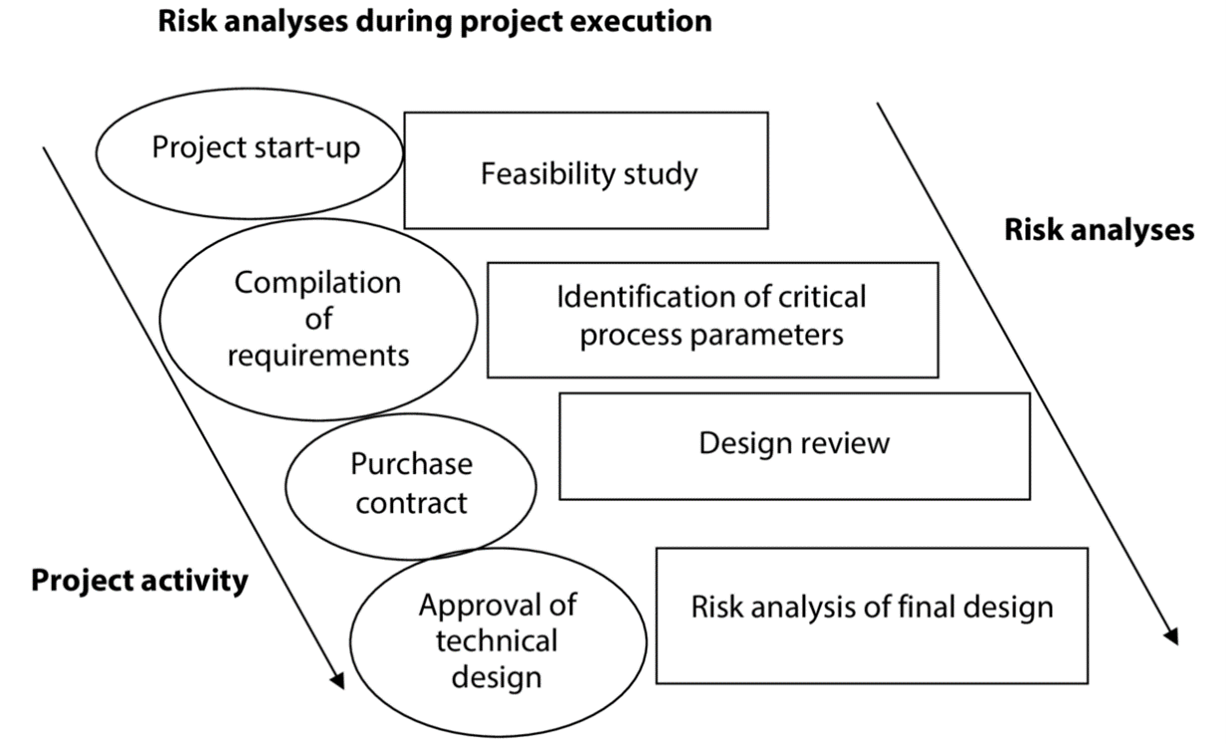

From the start of the project to the release of the technical design: Risk analysis is a constant companion.

Risk analyses can or must be carried out at different points in time within the process of procurement and qualification. Here is a brief outline of the phases of risk analyses in project implementation.

Typically, a project starts with a feasibility study, which in itself is a risk analysis. The next step (identification of critical process parameters) should be to determine what risk the equipment poses to the product. This should be done as part of the requirements gathering to support the identification of Critical Process Parameters (CPP) and Critical Quality Attributes (CQA).

The classification of the equipment in relation to the process can be done as follows:

- Critical (C): Malfunction can lead to violation of GMP requirements with influence on product quality and patient safety.

- Major (Ma): Malfunction can lead to a direct, undetectable violation of GMP requirements with no impact on patient safety.

- Minor (Mi): Malfunction may result in an observable violation of GMP requirements with no impact on patient safety.

- Not applicable if there are no GMP requirements.

In the design phase, a risk analysis is carried out to identify risks due to process or design changes, pipe routing as well as arrangement of sensor technology and to still act on the design, equipment and monitoring devices in time. Based on the drawings (P&ID, equipment design drawings) and other specifications (functional descriptions, hardware specifications), the evaluation of the equipment and the determination of the measures to minimise the risk takes place.

The following measures are possible:

- Modification of functions, programme steps or system parts

- Verification in installation, functional and performance qualification

- Conducting studies and trials in advance

- Additional monitoring measures

- Regular calibration

- Maintenance activities

- Administrative measures/addressing in SOPs

To trace all measures in the qualification, a proof of completeness (traceability matrix) must be provided. This can be done by referencing test protocol numbers, SOP numbers, maintenance plans, etc. in the risk analysis. Reference must be made in the qualification report to the fact that all risk reduction measures have been taken.

Do you have any questions or suggestions? Please contact us at: redaktion@gmp-verlag.de