The Power of the Comma or: What do Print Data have to do with Drug Safety?

5 min. reading time | by Doris Borchert

Published in LOGFILE 12/2020

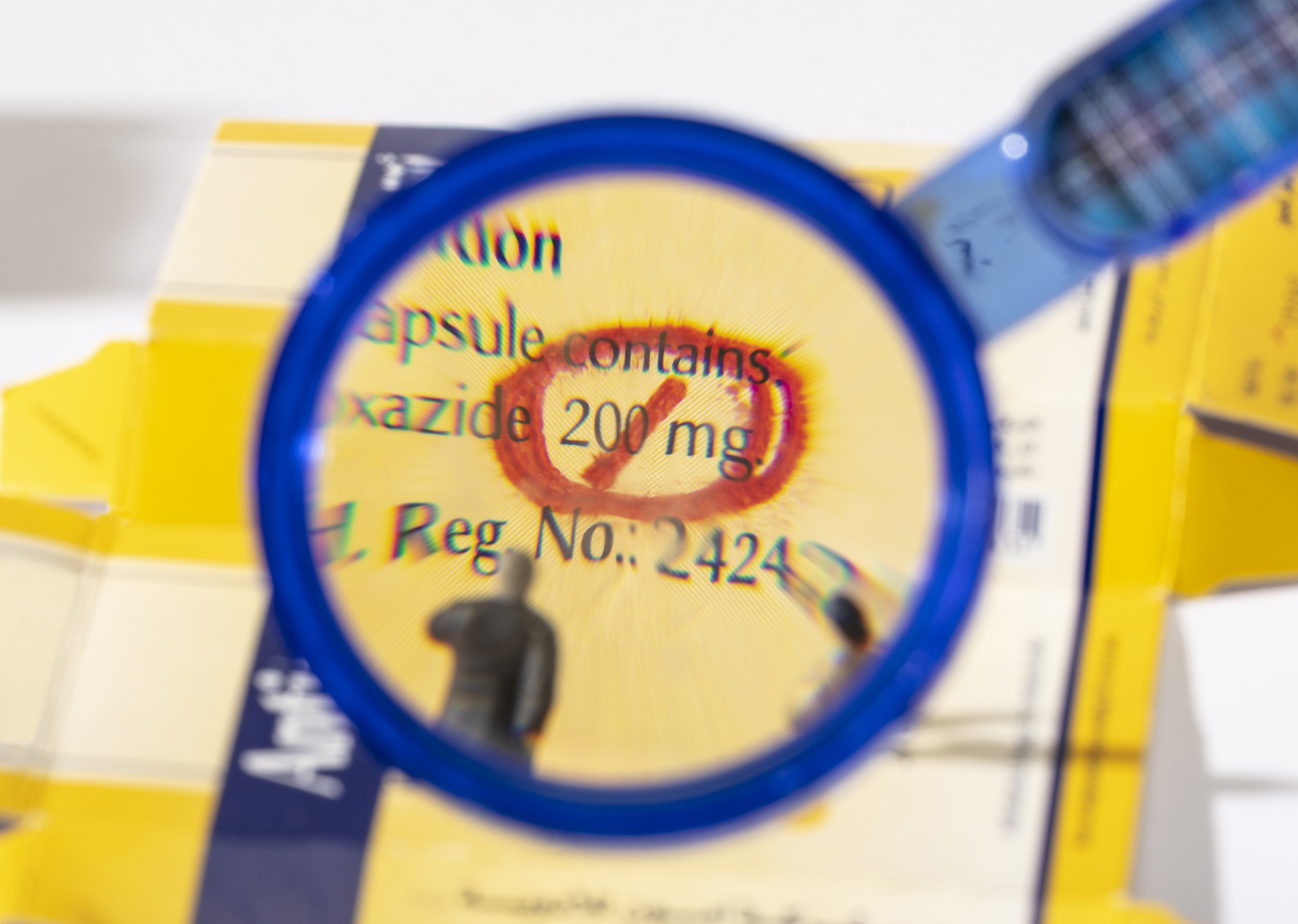

Would you have known? Around 90% of all product recalls by pharmaceutical companies are due to errors in printed packaging materials. It is not the quality of the drug per se that calls patient safety into question, but incorrect or faulty information on the packaging.

The place of a comma on our bank statements can bring tears to our eyes or put a smile on our lips. However, the incorrect positioning of a comma when indicating a dosage quantity represents a serious patient risk. For example, the 4.0mg specification on paper "only" differs by a comma of 40mg - but de facto there is a factor of 10 behind it, which under certain circumstances can decide over life and death.

The generation of print data and drug safety are therefore closely related. Reason enough to pay more attention to this topic!

The interview with Ilka Henkel and André Deister provides a short and interesting insight into the subject of print data management. Both are the authors of the GMP Compliance Adviser Chapter "GMP aspects when handling print data".

Ms. Henkel, you write that incorrect dosage information has repeatedly led to recalls in the past. How can such mistakes be avoided?

To avoid such errors, the processes involved in the creation of digital print data must be carefully defined and controlled. This also applies to the release process after changes have been made.

Mr. Deister, what are print data actually?

That's a good question! It already shows that the pharmaceutical entrepreneur as client and the printer or repro company as contractor often have little understanding for each other's interests. For example, the question "What is print data?" is not always answered the same way on both sides of the supply chain:

- For the pharmaceutical entrepreneur, it is the contents that are placed (printed) on a packaging material in combination with the technical data, such as the punch contour, code representations and security features.

- For the printer, it is the data that has to be multiplied and, for example, efficiently placed on a print sheet.

Ms. Henkel, what does this mean for print data security?

Safety is one of the most important issues in the pharmaceutical industry. The security of print data is equivalent to the security of the product. This includes the creation, the change including the change history, the transfer from the creator of the data to the printer and back as well as the archiving of the print data. Each individual process step must be described and authorized by the parties involved. Validations and risk assessments are essential.

Mr Deister, who is usually responsible for these procedures?

In practice, the creation of print data is often done by external repro houses. In this case, the same requirements apply to external type studios as to packaging suppliers. It should be noted that both internal and external type studios must be audited.

Ms. Henkel, what requirements do you think an external type studio has to meet?

The basic requirement is that external type studios have a high level of technical printing knowledge. The technical equipment should be up to date with the latest developments. In addition, the type studio should, if possible, have many years of experience in creating print data. In my opinion, an open and trusting relationship between client and contractor is indispensable.

And what steps are required to establish an external type studio?

First of all, the selection criteria must be defined. Once a suitable studio has been found, a test phase follows, during which the systems should also be validated. The next step is an audit. Once everything has been completed to your satisfaction, nothing more stands in the way of signing a contract.

Ms. Henkel, Mr. Deister - thank you very much for this brief but informative insight into the subject of print data management!

Do you have any questions or suggestions? Please contact us at: redaktion@gmp-verlag.de